The importance of innovation to the nuclear industry

A comment caught my attention at a recent nuclear industry event. The comment was that a hi-profile agency with a mandate to do research in advanced technology across industries had no interest in attending any events to learn more about nuclear power – primarily because “nuclear is not innovative”. In reality, there are numerous examples of how the nuclear industry has and continues to improve through innovation.

In exploring this comment, what we found was a belief (likely more prevalent than we would like) that renewables like wind and solar as well as various storage technologies are moving forward, innovating to become the energy source of the future, while old technologies like nuclear are past their prime heading into old age.

The discussion then moved to future reactor designs as proof of innovation in the nuclear industry. Look at fast reactors, thorium reactors or even SMRs. Although these are all interesting, it was pointed out that these represent “novelty”, not innovation. And to argue that a novel design is what is required to save the industry (although they will come) gives the message that today’s designs are just not good enough – and that is absolutely not true.

The public looks at nuclear power and sees a staid industry, some think in decline, that is building technology that has been around for 50 years. Granted some nuclear projects continue to be built above budget and over schedule, while other “newer” technologies continue to improve and reduce cost and schedule – as would be expected when developing technologies of the future.

However, there are numerous examples of innovations across the nuclear industry. For example, China has made improvements to the Daya Bay CPR1000 design at Lingao. They increased the output by about 100 MW through an improved turbine, and made great advancements to the control systems by adding distributed control. At Nuclear Power Asia in Vietnam this past month, a presentation by Mitsubishi showed how they improved their construction schedule from 77 months to 50.5 months from the Ohi 1 project to Ohi 3. Westinghouse is learning lessons from its experience in China and is applying them to their AP1000 projects in the US using advanced modular construction technology. And here at home in Canada where Bruce Power, whose tag line is “Innovation at work”, has found ways to increase the life of its reactors well beyond what was thought possible only a few years ago.

The analogy can be made to cars. The cars we drive today are very similar to those we drove 30, 40 and even 50 years ago. Four wheels, combustion engine, rubber tires. But are they really? In fact almost nothing is the same. Our cars today are full of electronics controlling the engine; the bodies no longer rust away in a few short years, safety has been greatly improved through air bags and other enhancements; and tires rarely go flat so that many models no longer carry spares. In fact technology has advanced in leaps and bounds in the cars we drive every day. And even though we are now looking at next generation technology such as electric and hydrogen powered cars, these are still novelties. These types of advancements are not required to innovate our vehicles. In fact the opposite is true. It is the innovation in the everyday systems in our cars that continue to make them better. And the magnitude of these improvements is staggering.

Somehow this message is not getting through with our nuclear plants. It may be because we operate in a very rigorous regulatory environment that forces nuclear utilities to be extremely conservative as change creates risk. Add to that the magnitude of the capital investment in a nuclear plant and the conservatism increases further as the risk of an advancement is always taken into consideration when looking to the future.

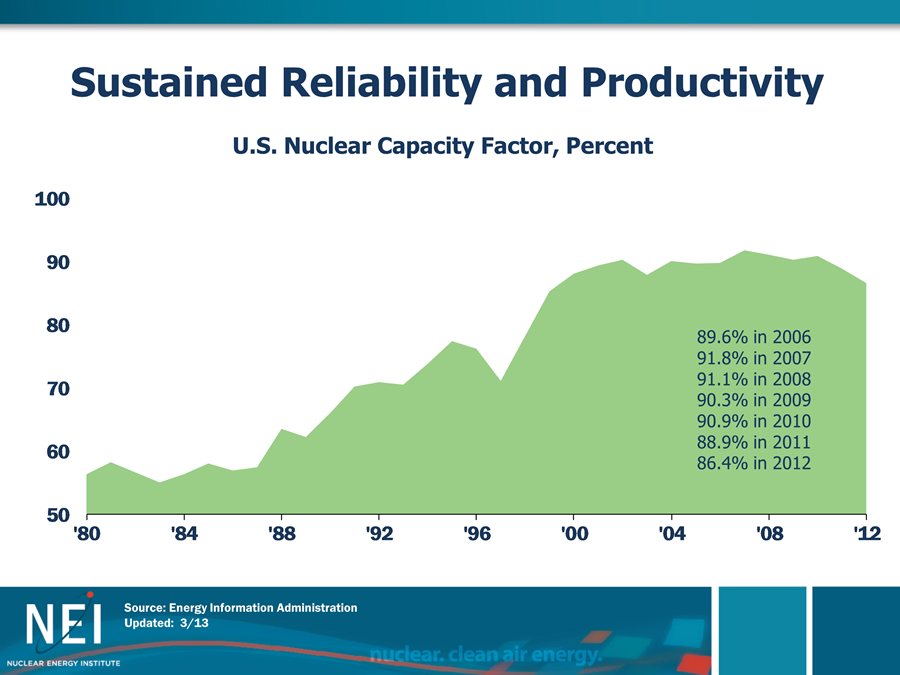

That being said, the operators of today’s fleet of nuclear plants have made incredible improvements to the operating fleet. This is why capacity factors (percent of maximum possible production) today can be 90% +. Back in the 1980s, a capacity factor in the mid 80% range was considered excellent. But no more. Today we expect better performance from our plants and we get it-through everyday innovation!

Source: www.nei.org

When it comes to operations, the improvements are easy to show through improved performance of the operating fleet. The issue we have had in the west is an insufficient number of new build projects to show the innovation that is happening every day in this industry when it comes to new projects. New build in western countries have had a rocky start after decades of not building. But as we move forward, this too will improve.

For new projects, we need to not only be building to budget and schedule, but also showing that costs and schedules are reducing with time. The Koreans, Chinese and Japanese have clearly demonstrated the benefits of standardized fleets to reduce costs and schedules as they build more and more plants. We see them innovating as they learn from each project and move on to the next one. We are already seeing improvement in the US as the Summer plant is taking advantage of lessons learned from the Vogtle plant; and both are benefiting from the experience in China.

We must be able to demonstrate that today’s nuclear technology is a technology of the future and that advancements are indeed coming that make every project better than the last. If an agency looking to the future of energy thinks there is no innovation in nuclear, then we need to be more vocal about our achievements. We need to celebrate our innovation. And we need to continue to invest in further innovation because there is always room to get better.

Our strength is through our performance. And our performance continues to get better through innovation, each and every day. For those of you who have good examples of where innovation has benefited the industry, please post them as a comment.