China and Nuclear – my visit to Daya Bay Nuclear Power Plant

As stated in my previous post, I was in Hong Kong recently. This gave me an opportunity to visit the Daya Bay Nuclear Power Plant. This is not my first time visiting a nuclear power plant in China. I have visited Qinshan many times, and in fact have been involved in work for the Qinhsan CANDU units (after all I am Canadian). However this visit to Daya Bay gave me a new perspective on the Chinese nuclear program.

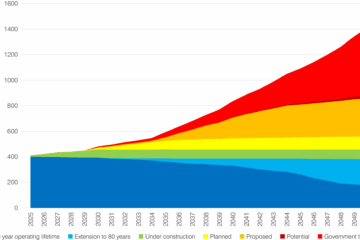

Most people are aware that nuclear power in China is booming. With 12 units in operation (about 10 GW), there are now 25 units under construction. The original target of reaching 40 GW by 2020 has long been abandoned with the more recent 60GW target now also being a thing of the past. Looks like China may achieve as much as 75 to 80 GW by 2020 and a whopping 140 GW by 2030. With more than 160 cities having more than 5 million in population it is easy to see the need.

Even though it is easy to be in awe of this program, we also need to understand that even with this growth, nuclear will only increase from its current 2% share of electricity generation to about 5% during this timeframe. Coal continues to be king with about one new coal plant being commissioned every week! China is adding about 100 GW of generation, primarily coal, to the grid every year! (Nearly Canada’s total installed supply, every year!!)

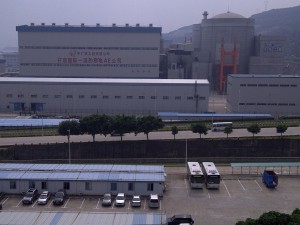

Daya Bay was China’s first nuclear plant and is a joint venture between the China Guangdong Nuclear Power Company (CGNPC) and China Light and Power (CLP) who import much of the power to Hong Kong. The site actually has three two unit stations, Daya Bay, Ling Ao 1 and Ling Ao 2. Daya Bay has been in service for 15 years while the first unit of Ling Ao 2 was declared in commercial operation earlier this year with the last unit going into service next year.

All 6 units are based on the Areva 900 MW design. Localization has continued to increase and is getting close to 85% for future units. This design is now the backbone of the Chinese program and is known as the CPR-1000. There are currently 20 of them under construction!

While the nuclear side of the plant remains the same, the design has not stood still. The newest units have a higher output due to an improved Turbine Generator and secondary systems as well as having an up to date digital control system. Clearly the Chinese are doing what we all know, or should, is the right approach to a successful program – large scale standardization and series production. The result is a robust design that can evolve with time with projects having relatively low risk and even lower cost.

I am not suggesting that any one design is better than any other, but rather the fact that the standardization program is paying off in significant benefits. The training program at Daya Bay (1000 new recruits per year) which supports the entire CPR-1000 program is testimony to the merits of such a standardization program. I am sure China will achieve the same with their domestic AP-1000 program (based on Westinghouse technology).

Reading this past week that South Africa is now changing its views on proceeding with its own revitalized program by considering plants supplied form either Korea or China to reduce cost is telling. The industry is changing. Most of the world’s new build is in Asia and the benefits of a large standardized program there should benefit the industry around the world. Yes, just maybe a design supplied from Korea (as was the case in the UAE) or from China will be more cost effective due to their vibrant domestic programs. However, the Western suppliers will not stand still either in the face of this competition and will find ways to work with Asia and compete more effectively around the world. This has been recently acknowledged by EDF in a seminar in China where they noted that “industrial progress happens where the plants are being built” as they seek to increase their participation in China.

The winners are the customers as, after a decade of rising nuclear costs, the time has come to reap the benefits of standardized global fleets. Everybody wins!!